The first butter grading service program began back on July 14, 1924, in Minnesota with an interest in advancing the sale of good-quality butter by using requirements for grading, packaging, and merchandising. This program has been further developed into the USDA Grade Label Program with grading services offered throughout the United States. The USDA U.S. Grade AA shield represents that the product has been evaluated by a skilled, licensed grader based on the U.S. Grade Standard for Butter to determine that the flavor, body, and texture meets the highest quality standard for butter.”

-

Butter is made exclusively from milk or cream with or without common salt, and with or without additional coloring matter, and containing not less than 80 percent by weight of milkfat. Butter is produced by churning cream until fat is separated from liquid (buttermilk) and moved through working and texturizer sections of the churn until it’s in a semi-solid state. The butter leaves the churn and enters a butter boat or silo and is then pumped over to packaging machines that will package butter ready for consumer use. Butter packaging includes ¼ lb sticks and 1 lb solids in Elgin or western styles, continental chips and Hassia-style butter cups, 25 KG, and a variety of other styles.

Continuous Butter Churn

Working Butter in the Churn

1 lb Elgin Style Solids Packaging Machine

25KG Bulk Butter Filler -

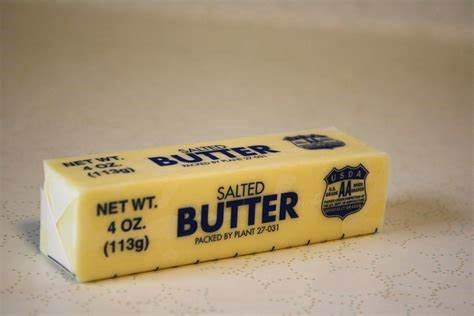

USDA offers grading services for a wide range of styles of butter. Butter is evaluated by trained, licensed USDA graders following the United States Standards for the Grades of Butter. Graders will select random samples from each lot of production, temper between 45-55°F, and pull a plug to evaluate the sample for flavor, body characteristics, color, and salt (if salted).

.

Flavor

Flavor is determined by organoleptically evaluating a portion of the sample for taste and smell. Butter shall possess a fine and highly pleasing butter flavor.Flavor Characteristics in Butter

• Acid

• Neutralizer

• Aged

• Old Cream

• Bitter

• Scorched

• Coarse

• Smothered

• Cooked

• Storage

• Feed

• Utensil

• Flat

• Weed

• Malty

• Whey

• MustyBody, Color, and Salt

A plug will be removed from each sample and evaluated for body characteristics, color, and salt. Butter shall have an attractive appearance and be free of moisture on the front and backside of the trier. Color shall be even shades of yellow. Salted butter shall be balanced to enhance but not overwhelm the natural butter flavor.Body Characteristics

• Crumbly

• Ragged Boring

• Gummy

• Short

• Leaky

• Sticky

• Mealy or Grainy

• WeakColor

• Color Specks

• Streaked

• Mottled

• Wavy

Salt

• Gritty

• SharpDetermining the Final Grade

Flavor, Body, Color, and Salt characteristics are evaluated on a slight, definite, or pronounced degree and the sample will receive disratings based on these sample characteristics. The total number of disratings will determine the overall grade of the sample.

- U.S. Grade AA

- U.S. Grade A

- U.S. Grade B

Butter that fails to meet the maximum disratings for U.S. Grade B will receive no grade assigned.

For more information on U.S. butter grading standards reference:

-

If you are interested in having butter graded by the Dairy Grading Branch, please contact DairyNFO@usda.gov.

-

What are the benefits of Grade Label Product?

- Promotion for manufacturers to create marketing opportunities

- Value added product

- Product is evaluated based on the U.S. Grade Standards for Butter for measurable attributes for flavor, body, and texture

- Assures the consumer that the butter they purchase has been evaluated by highly skilled graders based on established grading standards

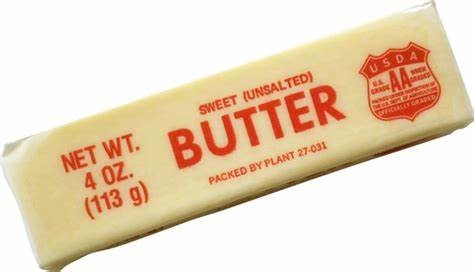

Guidelines for USDA AA Grade Label Shield Program

- Grading Requirements In 918I, Section 7, Subsection F, as outlined in 7 CFR, Part 58 Subpart A

- Food and Drug Administration Regulatory Labeling Requirements, Code of Federal Regulations: 21 CFR 101

Grade Label Shield Packaging Requirements

- Shield shall be at least ¾” x ¾”

- Exceptions are made for smaller packaging such as continentals, butter cup/Hassia style foil

- Distributor/manufactured-by information shall be on packaging

Some Types of Approved Packaging

- Wrapper (Parchment, foil, etc.)

- Cartons (1#, 4#, Chip boxes, etc.)

- Shipping boxes

- Whip tubs and lids

- Foil (Hassia cups or continentals)

To receive approval on grade label packaging, submit a completed DA-155 for new facilities and distributors. Once the distributor/facility are approved, submit a DA-156 with the packaging seeking approval for grade label use.

For additional questions regarding grade label packaging, please contact:

Allison.reynolds@usda.gov Grade Label Program Coordinator

Remote Butter Grading Program

The USDA AMS Dairy Program Grading Branch has established a Remote Butter Grading Program, allowing more butter manufacturers to access to new marketing opportunities providing dairy farmers additional opportunities to market milk for use in a value-added product.

- Remote Butter Grading Program Factsheet (pdf)

- Webinar: https://www.zoomgov.com

Passcode: !u+j2?Xf

Plant Records to Include Grade Label Butterfat Testing

USDA Dairy Program Grading Branch aims to enhance efficiency by reviewing records and aligning with current industry butterfat testing practices ensuring quality and compliance with USDA Grade Label Requirements. Follow this link to view the Industry Informational Webinar and Butterfat Program Launch-Customer Guidance.